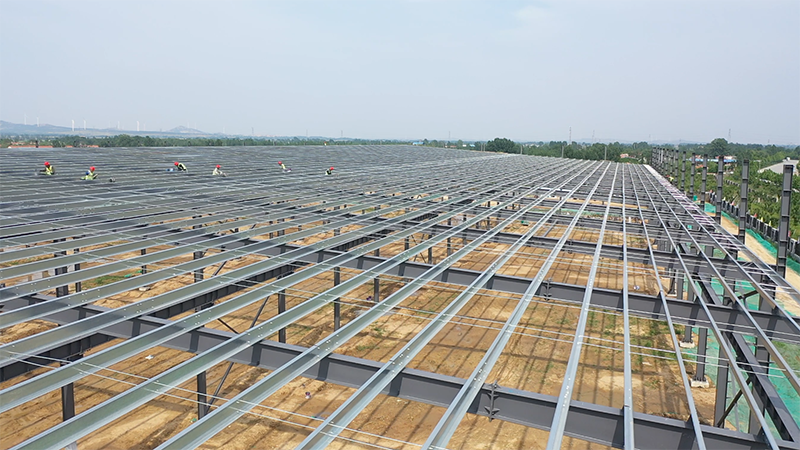

Steel structure prefabricated building is a new environmentally friendly building,it is trend of building in future.Nearly all kinds of building could be built by steel structure design system including civil building,commercial building,industrial building,agricultural building and so on,Compared with traditional concrete buildings,steel structure building is better in structure strength,anti-earthquake and space utilization.Installation is quick due to prefabriated components.Moreover,because steel id reusable,so,it is more environmentally friendly.Now,steel structure technology is a mature technology in high-rise building and super high-rise buildings.It has became mainstream in construction design.

1.Quick installation:

All steel structure parts are pre-fabricated in the factory and then shipped to the site for direct installation. Customers do not need to be welded at the site, reducing installation time.

2.Ample internal use space:

The steel structure prefabricated building has a large span, except for the pillars supporting the roof steel beams on both sides,there are no pillars inside. The forklift will not encounter obstacles during internal travel, which significantly improves the used space.

3.Building materials can be recycled:

90% of the steel structure prefabricated building materials can be recycled, which improves the reuse rate of materials.

4.Environmental-friendly

During the construction process, there is no construction waste and dust, no water is needed, water saved, and there is no noise, which will not affect the average life of surrounding residents.

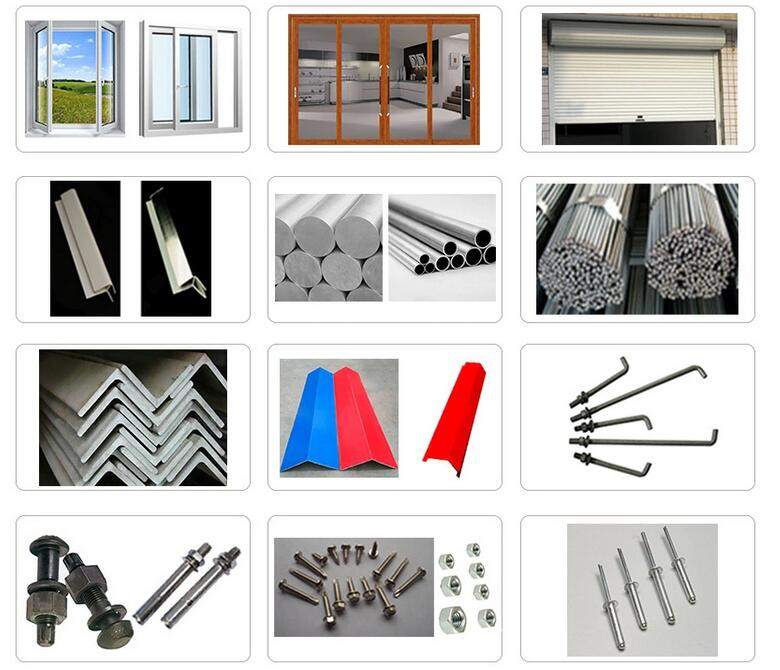

| 1 | Steel structure | Q235 or Q345,column and beam ,which are generally assembled and welded with hot-rolled H section steel or steel plates. |

| 2 | Purlin | Q235 or Q345,C or Z section channel |

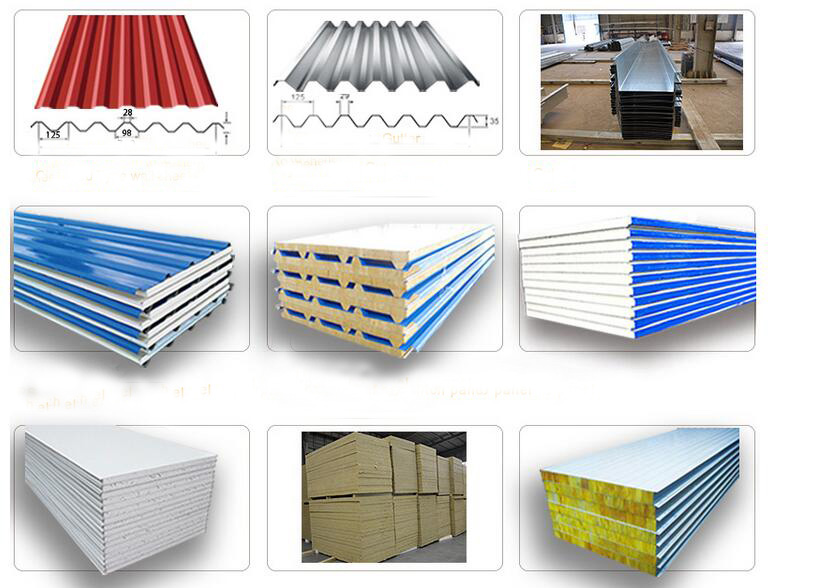

| 3 | Roof cladding | sandwich panel or corrugated steel sheet |

| 4 | Wall cladding | sandwich panel ,glass curtain,aluminium panel for choice |

| 5 | Sag rod | Q235,circular steel tube |

| 6 | Bracing | Q235,steel rod, L angle, or square tube. |

| 7 | Column&transverse brace | Q235,angle steel or H section steel or steel pipe |

| 8 | Knee brace | Q235,L 50*4 |

| 10 | Rainspout | PVC pipe |

| 11 | Door | Sliding Door/Rolling Door |

| 12 | Windows | Plastic Steel Window/Aluminum-alloy Window |

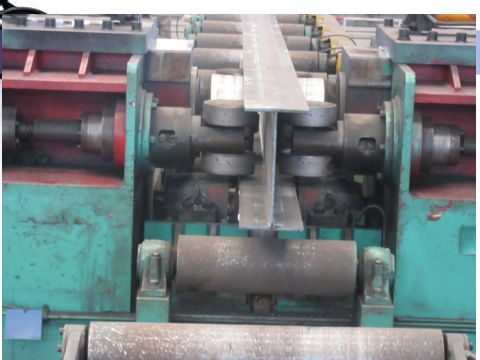

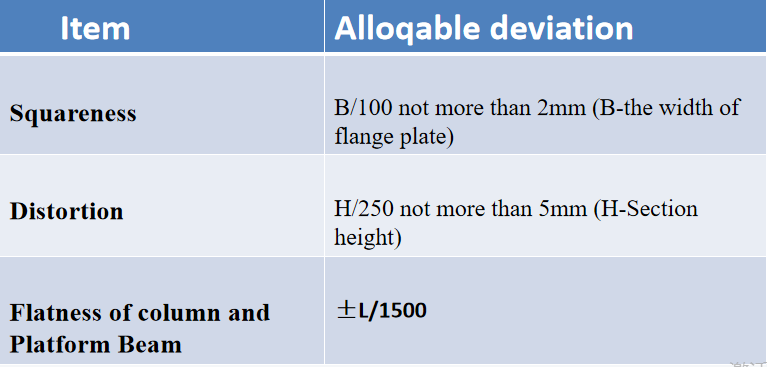

Checking specifications,quality and appearance of raw material,then cutting steel plate into sizes required by Numerical Control Cutting Machine.

Fixing the flange plates and the web.The gap between the flange plate and the web must not exceed 1.0mm.

Welding the flange plates and the web. The welding seam surface must be smooth without any holes and slags.

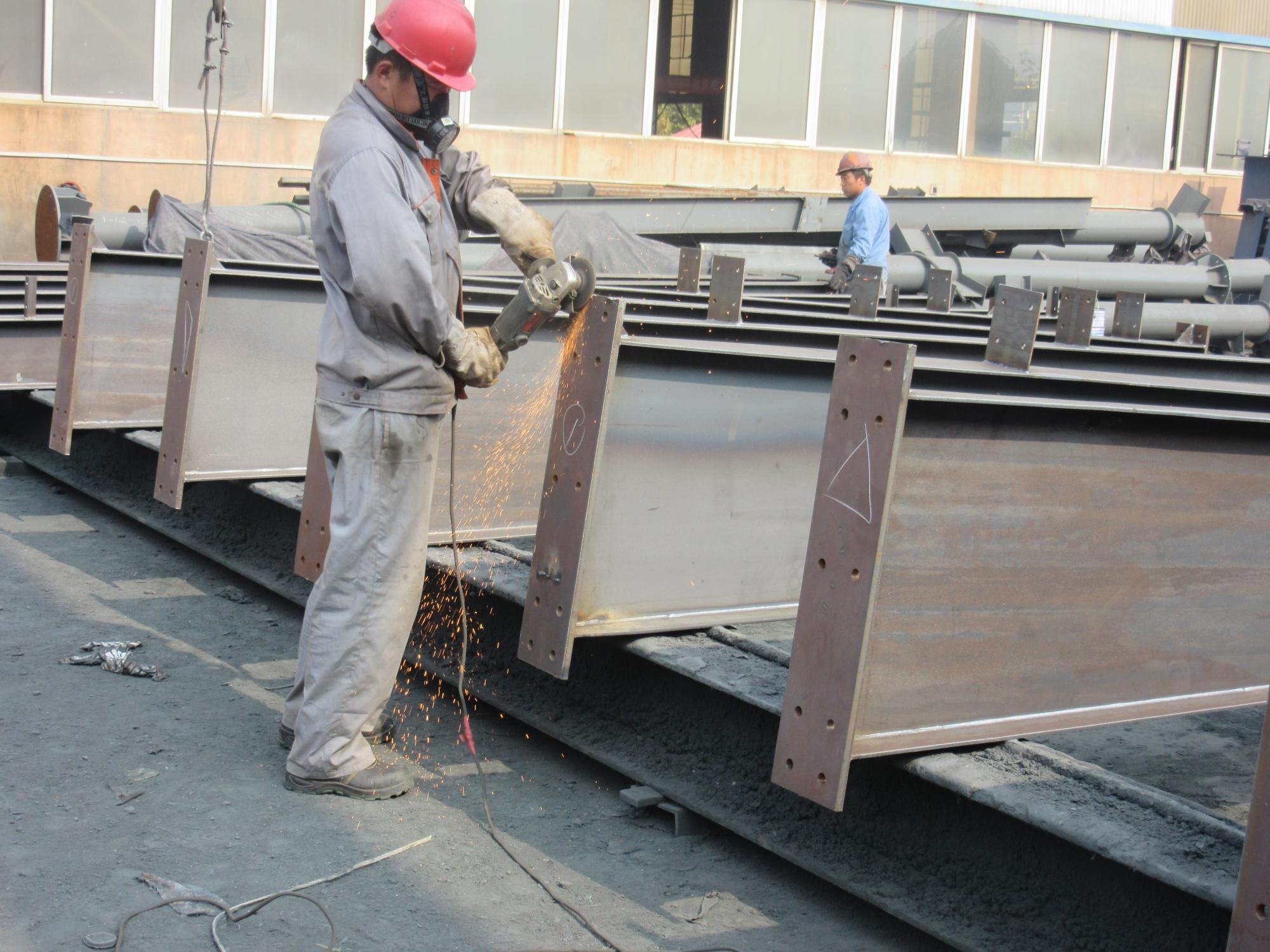

There will be greater welding deformation after welding the flange plates and web together, and also deviation of the squareness. Therefore, it is necessary to correct the welded H-steel by straightener.

After drilling, burrs must be cleaned up without damaging the base metal. If the deviation of the hole distance is beyond the specified scope, the quality of electrode must be as same as the base metal. Drill again after polishing smooth.

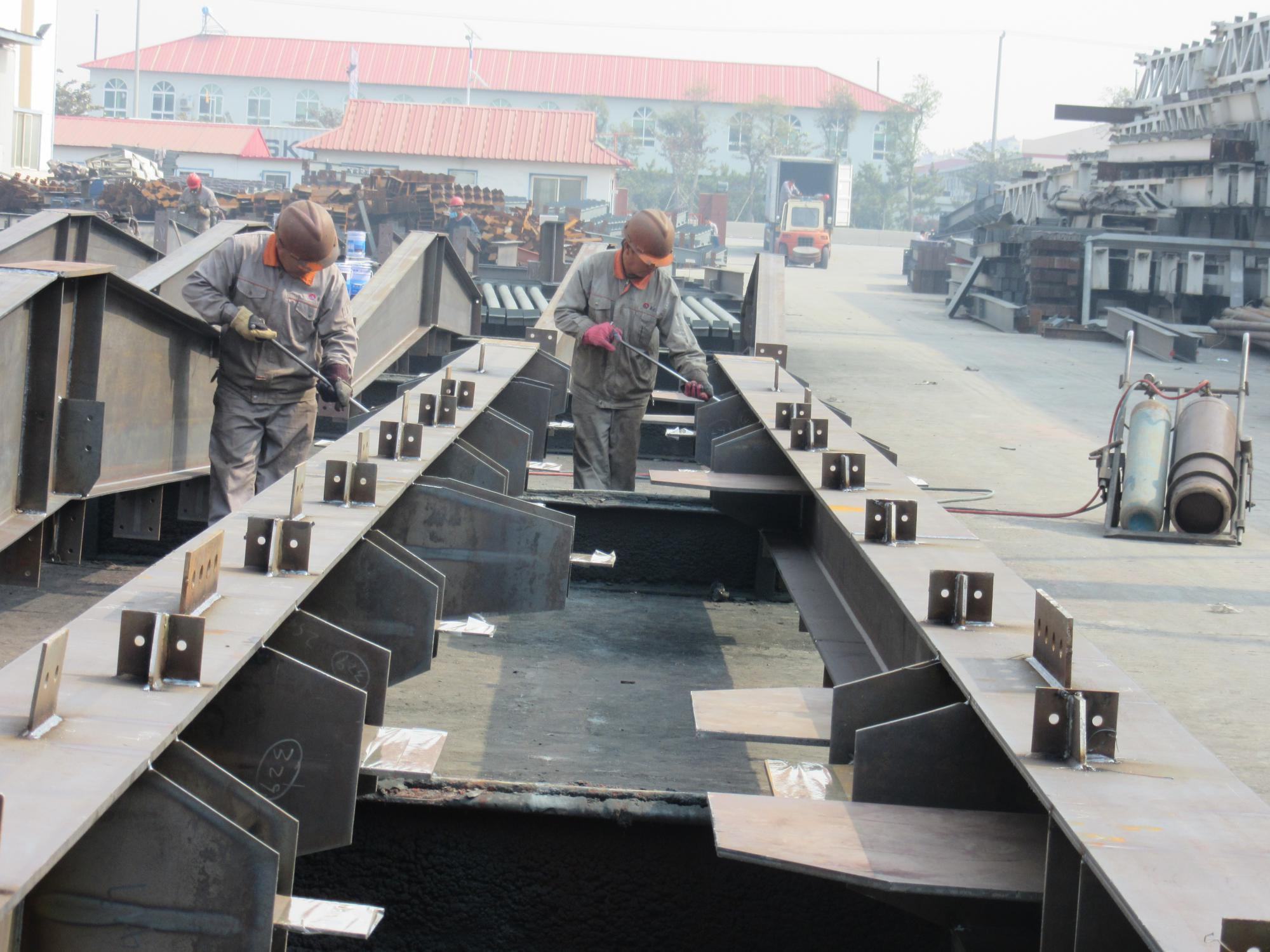

Strictly follow the drawing to assemble and consider the pre-welding shrinkage according to the characteristics of steel components. Then,continue processing after confirming without any error.

By shot blasting, the surface roughness will be gained, which can increase the adhesion of paint film and imporve the surface quality of paint and preservative effect.

Our installation teams are committed to ensuring your structure is a complete success and we have a technical team available to assist when queries arise in the workshop or on site. Special care is taken when delivering your components throughout the erection process.

Drawing and quotation will be offered within 1 day once the details are informed.Customized drawign are welcomed,it doesn’t matter even if there is no one.

A. Customers have the drawings

We can provide you the full service of production, shipment and

Installation guide, which is high quality and low cost. Because we own all kinds of technical facilities, complete test instruments and advanced production processes.

B. No drawings

Our excellent design team will freely design the light steel structure warehouse/workshop for you. If you give us the following information, we will give you an satisfactory drawing.

1. Dimension: length, width, ridge height, eave height, etc.

2. Doors and Windows: dimension, quantity, installation position.

3. Local Climate: wind load, snow load, roof load, Seismic load

4. Insulation materials: Insulated sandwich panel or corrugated steel sheet

5. Crane beam: If you need it, it will be very helpful that you tell us its technological parameters.

6. Usage: If you tell us the application of light steel structure warehouse, we can exactly design the drawings or match suitable materials for you.

7. Other requirements: such as fire proofing, transparent roof, etc. Please kindly inform us, too.

Packaging Details:

Steel frame will be packaged by customized steel pallet;

Fasten accerssories packing in wood carton;

Or as required

Normally is 40’HQ container.If you have specifical requirements,40GP and 20GP container are ok.

Port:

Qingdao port,China.

Or other ports as required.

Delivery time:

45-60 days after deposit or L/C received and the drawing is confirmed by buyer.Pls discuss with us to decide it.