A steel structure workshop is a metal structure made of structural steel members that are connected to each other to carry loads and provide complete rigidity. Steel structure workshop is used for industrial production in which all steel structures are painted and then delivered to the project site for installation.It can be divided into light steel structure workshop and heavy steel structure workshop.This one is the light steel structure workshop, which is widely used in industrial buildings and civil buildings.It has many excellent characteristics such as light weight, big span, environmental friendly, low cost, beautiful appearance, etc.

1).Lightweight and high strength.

Steel structure good at resisting dynamic forces such as wind or earthquake forces.Besides,due to the high strength grade of steel, it is reliable and requires less raw material than other types of structures, such as concrete structures and wood structures.

2).Flexible and large span

Compared with the reinforced concrete building, steel structure workshop is more flexible with the large span,which meets the needs of the ample space. There is no column barrier inside, clear span, and vast internal space.

3). Environmental friendly.

Main steel frame materials can be 100% recycled, other materials can recycle as well,and pollution reduced during construction and dismantling.

4). Fast Installation:

The construction time of the steel structure warehouse building is short. As components are all prefabricated in the factory, and the site only needs to be assembled. It significantly shortens the construction period.

5).Performance:

The prefab steel warehouse is durable and easy to repair, and simple maintenance.

6).Appearance:

The steel structure workshop is beautiful and practical, with simple and smooth lines. The color wall panels are available in various colors, and the walls can also apply for other materials. So it is more flexible.

7). Lower Cost and long life

The steel structure workshop has a reasonable cost. Lightweight components can reduce the value of the foundation while quick installed saving the cost of construction.What’s More,it can be used more than 50 years

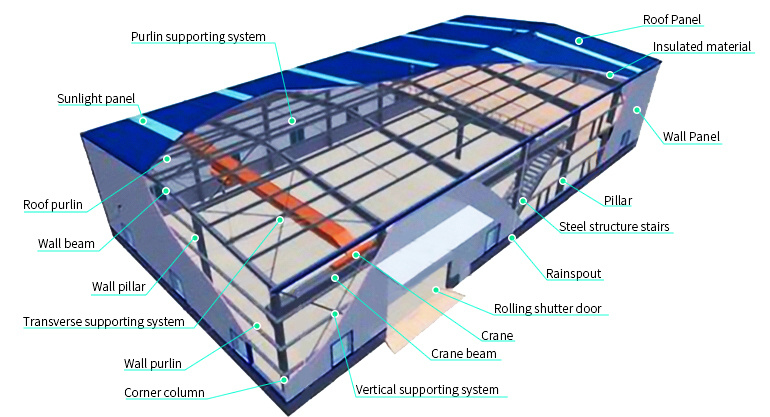

1.Main Frame

The main steel frame of steel structure workshop consists of column and beam ,which are generally assembled and welded with hot-rolled H section steel or steel plates.

2.Secondary Frame

1. Purlin

Purlins made of C-shaped and Z-shaped steel.

The purlins used to support the roof and wall panels and transfer the load from the roof and wall panel to the primary steel frame.

2. Bracing

There are roof bracings and wall bracings. The bracings usually made of steel rod, L angle, or square tube. The bracing system uses to stabilize the steel frame.

3. Sag rod

The sag rod is to link between the two purlins to adjust and control the stability of two adjacent purlins. Generally, sag rod made of rod with a diameter of 10 or 12mm.

3.Cladding system

Including roof and wall system,roof sheet and wall sheet alwanys using corrugated steel sheet and sandwich panel.Thickness of steel sheet can be 0.35-0.7mm,while color in sea blue,white grey and bright red are normal.If sandwich panle,EPS sandwich panel,fiberglass sandwich panle and rock wool sandwich panel for choice.

4.Covering sheet and Trim

These can let the steel structure workshop looks more nice,make it has better waterproof and thermal insulation performance.Covering sheet and trim usually adopt 0.5mm thickness corrugated steel sheet by bending.

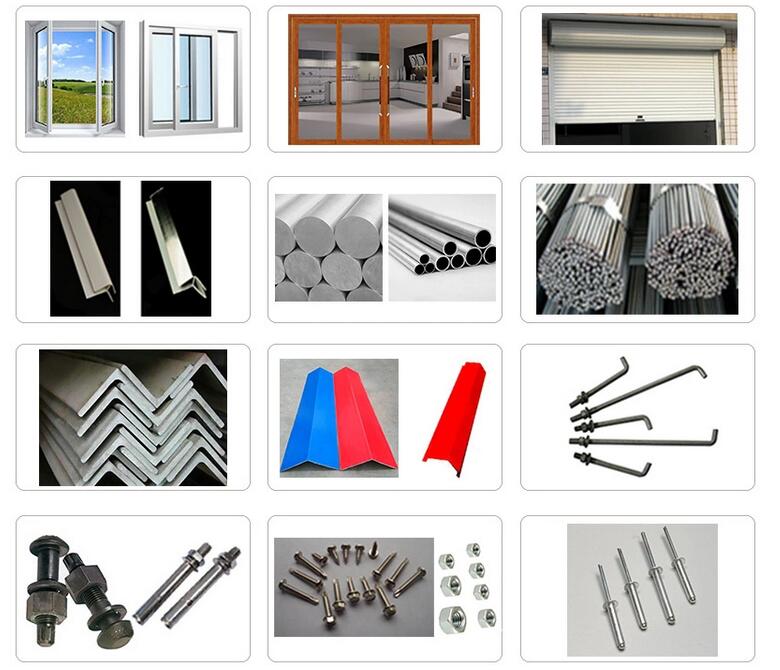

| 1 | Steel structure | Q235 or Q345,Welded H section steel or steel truss. |

| 2 | Purlin | C section channel or Z section |

| 3 | Roof cladding | sandwich panel or corrugated steel sheet |

| 4 | Wall cladding | sandwich panel or corrugated steel sheet |

| 5 | Sag rod | Φ10 steel rod |

| 6 | Bracing | Φ20 steel rod or L angle |

| 7 | Column&transverse brace | angle steel or H section steel or steel pipe |

| 8 | Knee brace | L steel |

| 9 | Roof gutter | color steel sheet or stainless steel |

| 10 | Rain spout | PVC pipe |

| 11 | Door | electric rolling shutter/sliding door |

| 12 | Windows | PVC/plastic steel/aluminum alloy window |

| 13 | Connecting | high strength bolts |

| Standard | GB.If others,pls indicate in advance. |

| Place of Origin | Qingdao city,China |

| Certificate | SGS, ISO ,CE ,etc. |

| Size | As required |

| Steel grade | Q235 or Q355 |

| Surface Treatment | Painted or galvanized |

| Color of paint | Mid-gray,white,blue or as required |

| Main material | Steel pipe truss,C steel,corrugated steel sheet,etc. |

| Accessories | High strengthen bolt,normal bolt,self-tapping screw,etc. |

| Design parameters | Wind load,snow load,the degree of earthquake,etc. |

| Design software | PKPM,Tekla,3D3S,Auto CAD,SketchUp etc. |

| Service | Guide Installation or construction on Site |

Q: Is your company a factory or trade company?

We are a factory, so you can get the best price and competitive price.

Q: Do you provide samples ? Is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: Do you offer designing service for us?

A: Yes, we could design full solution drawings as your requirements. By using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (X steel) and etc. We can design complex industrial building like office mansion, supermarket, auto dealer shop, shipping mall,

hotel.

Q:Do you offer installation service overseas?

Yes, installation instruction and video will be provide, or we can also send our engineers to your site as installation guide, they will teach your people how to build project.we have our own construction team consist of skillful workers and professional engineers.They have been to many countries and regions for the steel structure construction.

Q: How long is your delivery time?

A:Generally 30-45 days after received the deposit and confirmed the drawing by buyer.

Q: What is your terms of payment ?

A: Payment≤1000USD, 100% in advance. Payment≥1000USD, 50% by T/T in advance , and balance before shipment.

Please kindly inform us information as below if you are interested in our products.

1.Location: In which country will be built?

2.What’s the design parameters of the location?

2.1 Wind load in KN/㎡(or max. Wind speed in km/h in the past 50 years),

2.2 Snow load in KN/㎡(or the max. height of snow in the past 50 years)

2.3 The degree of earthquake.

3. .What’s the dimension?

Pls indicate the length,width as well as the height.

4. What material will be used for roof and wall?

Will be designed according to the buyer’s request,EPS sandwich panel,fiberglass sandwich panel,rock wool sandwich panel,PU sandwich panel and corrugated steel sheet are recommended.

5.Crane : Are there cranes inside the steel structure?

6.Other requirements of yours?